BOILER WATER CHEMICALS

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.

The quality and characteristics of water fed to a steam generator to replace that lost by evaporation end blow down have a profound effect on the performance, life and safety of the boiler. The chemical and physical

developments within the boiler are influenced by the composition of boiler water.

Boiler Water treatment is required for fast safe and reliable steam generation by preventing pitting- corrosion, scaling and carryover. Boiler feed water should be free from calcium, magnesium, silica, iron, DO,

turbidity which imply poor heat transfer, increased fuel consumption, ultimately it leads boiler destruction.

Boiler or heater treatment program should be consisting of oxygen scavengers, multifunctional polymers, organic/inorganic phosphate conditioners, antifoaming chemicals, alkalinity builder and various amines.

Aqua fine treatment chemicals include number of products formulated for the control of corrosion, deposition, foaming, and carryover and condensate corrosion. Our treatment program for steam generation system

might include recommended treatment chemicals, feeding procedures, control units and instrumentation for monitoring and control. To assure that a steam generation treatment program performs as careful monitoring of

all critical parameters is required.

Our Product Range

- Catatalyzed Oxygen Scavenger

- Sludge Conditioner Treatment

- Scale Inhibitor

- Alkaline Scale Inhibitor

- Corrosion Inhibitor

- Filming Amine Treatment

- pH Booster

- Silica Inhibitor

- Descalant

COOLING WATER CHEMICALS

Cooling water treatment program is integrated part of all industries. Four or more problems occur with cooling water system operation like & metallurgical failure and breaks corrosion scaling, fouling, microbiological growth. Ultimately it leads poor

heat transfer, quality of the process open and close recirculation system.

Program consists of cathodic, anodic and adsorption co antiscalant/dispersant, micro biocides which facilitate clean heat transfer surface, lowers all types of corrosion and minimize fouling thus keep cooling

tower fins and louvers clean and free from algae fungus and slime growth.

Our Product Range

- Scale And Corrosion Inhibitor

- Corrosion Inhibitor

- Scale Inhibitor

- Silica Inhibitor

- Bio Dispersant

- Dispersant

- Water Softener

- Biocides For Paper Industries

- Biocides For Sugar Industries

- Oxidizing Biocides

- Non Oxidizing Biocides

- Broad Spectrum Biocides

- Micro Biocides

FUEL CHEMICALS

Fuel additive is based upon either oregano silicon or amine based compound containing a unique combustion catalyst, which improves the combustion of fuel oil by reducing the fuel droplet size by the surfactant action of additives. The catalyst present

in fuel additives breaks the double bond in the long chain hydrocarbon molecule resulting in short chain hydrocarbon, having low flash point ignites easily & burns more rapidly.

Fuel additives also helps to reduce corrosion due to formation of SO3 gases and reduced excessive air/oxygen and stack temperature. A 1% reduction in excess oxygen approximately equal to 1% increase in efficiency.

When excess oxygen is reduced, so is stack temperature is also reduced. As per standard 5.5 degree Celsius drop in stack temperature provides 0.25% efficiency gain of boilers.

Our Product Range

- Fuel Additive

- Coal Additive

- Reduce Soot Formation And Slag Formation.

- Prevent Gum Formation And Corrosion.

- Reduce Wear & Tear Of Pumps And Injectors.

- Compatible To All Grade Of Liquid And Solid Fuel.

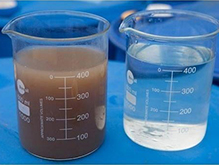

DESCALING CHEMICALS

Cleaning Chemicals quickly removes hardness and metal oxide deposits from boilers, heat exchangers, condensers, evaporations, cooling jackets, process vessels, piping and other equipment. It can be used while the equipment is on-stream or shut down.

Cleaning Chemicals can also be used to chemically clean well screens. It removes hard water scale, corrosion Products and iron deposits.

Cleaning Chemicals can be used for removes of rust and oxide / heat scale along with black oxide coating and chromium, zinc, And cadmium plate via the "immersion dip method" in metal processing applications.

Our Product Range

- Resin Cleaning Chemical

- Descaling chemical For Removing Silica Scale

- Descaling chemical For Removing Hard Scale

- Alkaline Descaling Chemical

- Alkaline Descaling Chemical for removing organic scale

- Organic Scale Remover

- Oil Dust Remover

- Neutralizer

- Descaling Chemical for SS metals

- Descaling Chemical for copper metals

- Descaling Chemical for bacterial growth

SPEACIALITY CHEMICALS

A suitable program is required to protect & extend the life of costly RO/UF & other type of membrane and maintain designed product water conductivity, flow and pressure by preventing precipitation of inorganic scales of carbonates, sulphates, oxides,

silicates, fluoride, iron etc.

Our RO Additives are highly suitable for feed water containing high silica, fluoride, sulphates, aluminium & iron oxides up to +3.00 LSI.

High performance RO Additive should be a perfect blend of phosphinocarboxylate and advance polymer or a aminophosphonate compound of higher chelation and distortion value in double deionised water to prevent precipitation

and reduce particulate fouling within membrane separation.

Our Product Range

- Polyelectrolyte / Flocculants

- Decolourant

- RO plant-Pre-Treatment Chemicals

- Defoamers / Antifoamers

- Acid Corrosion Inhibitors

- Corrosion Inhibitors

- Bio-culture

- RO Antiscalant

- Antifouling

- RO Membrane Cleaner

RO WATER CHEMICALS

Our Product Range

WASTE WATER CHEMICALS

Our Product Range

BIOCIDES - BIODISPERSANT

Our Product Range

SWIMMING POOL CHEMICALS

Our Product Range

WATER TREATMENT PLANTS (INDUSTRIAL - SOFTENING PLANT, DM PLANT, RO PLANT)

Our Product Range